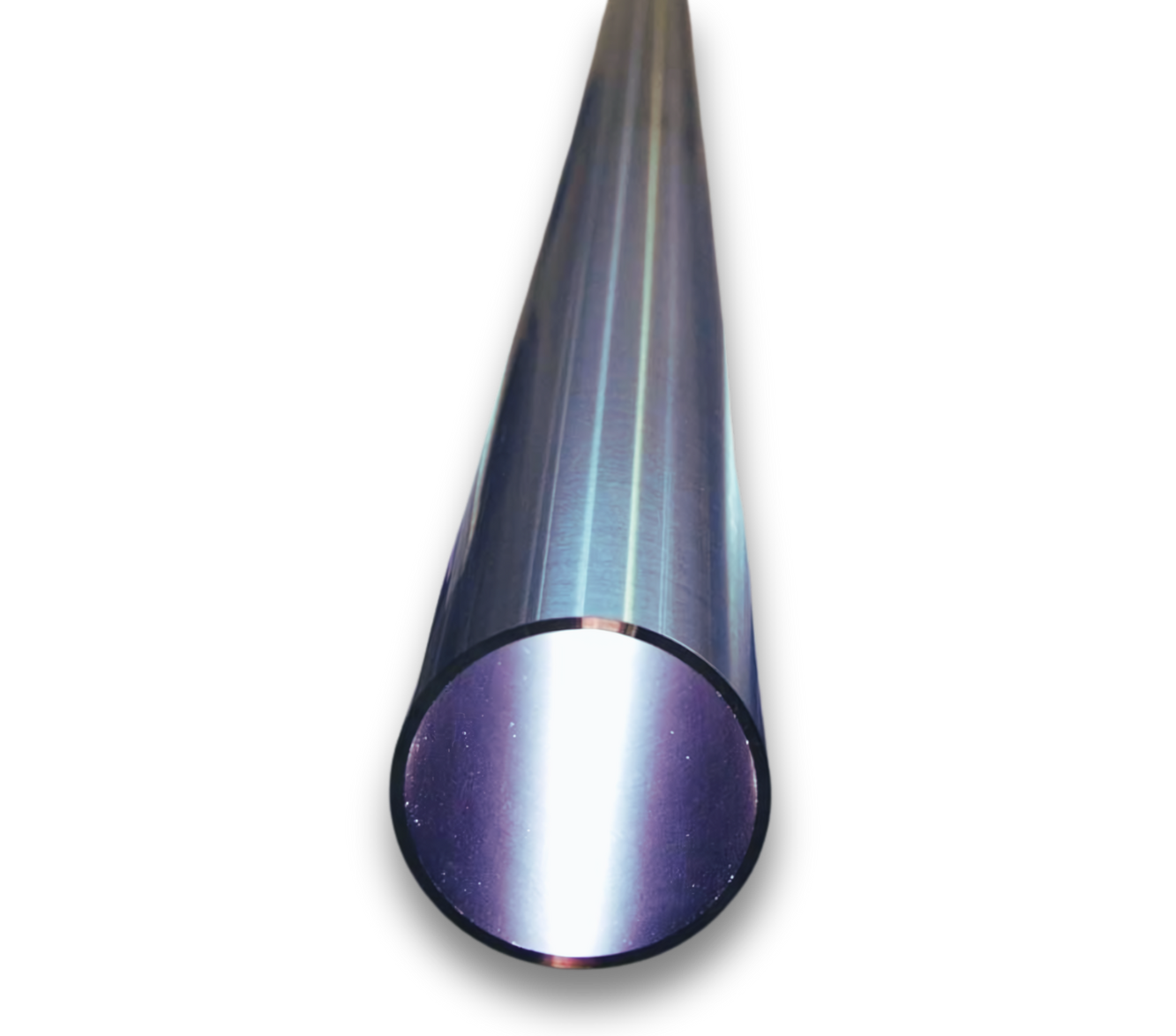

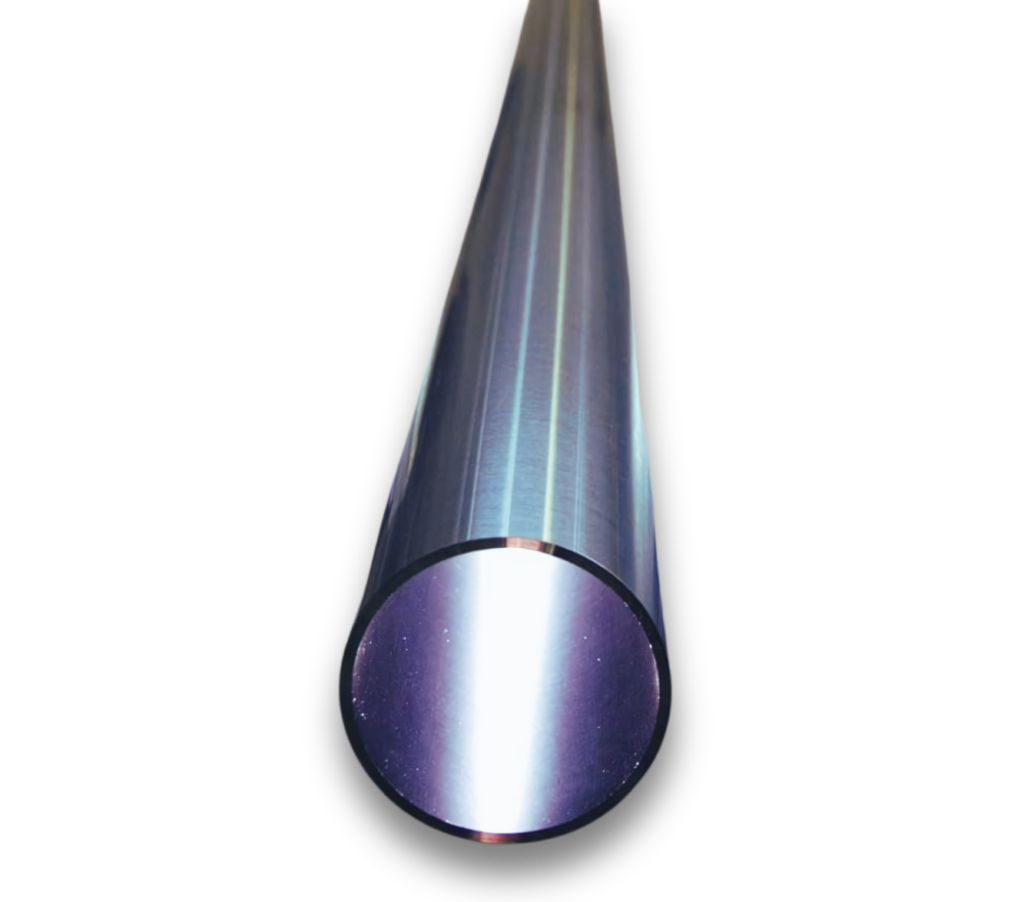

FAE Special Alloy Tubes

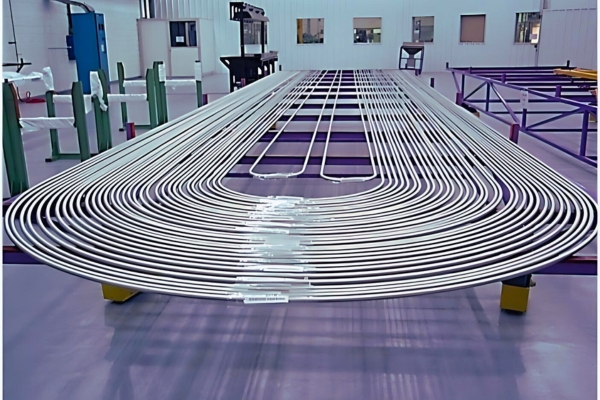

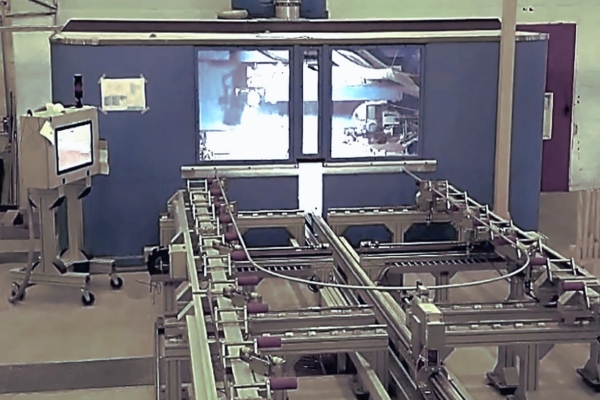

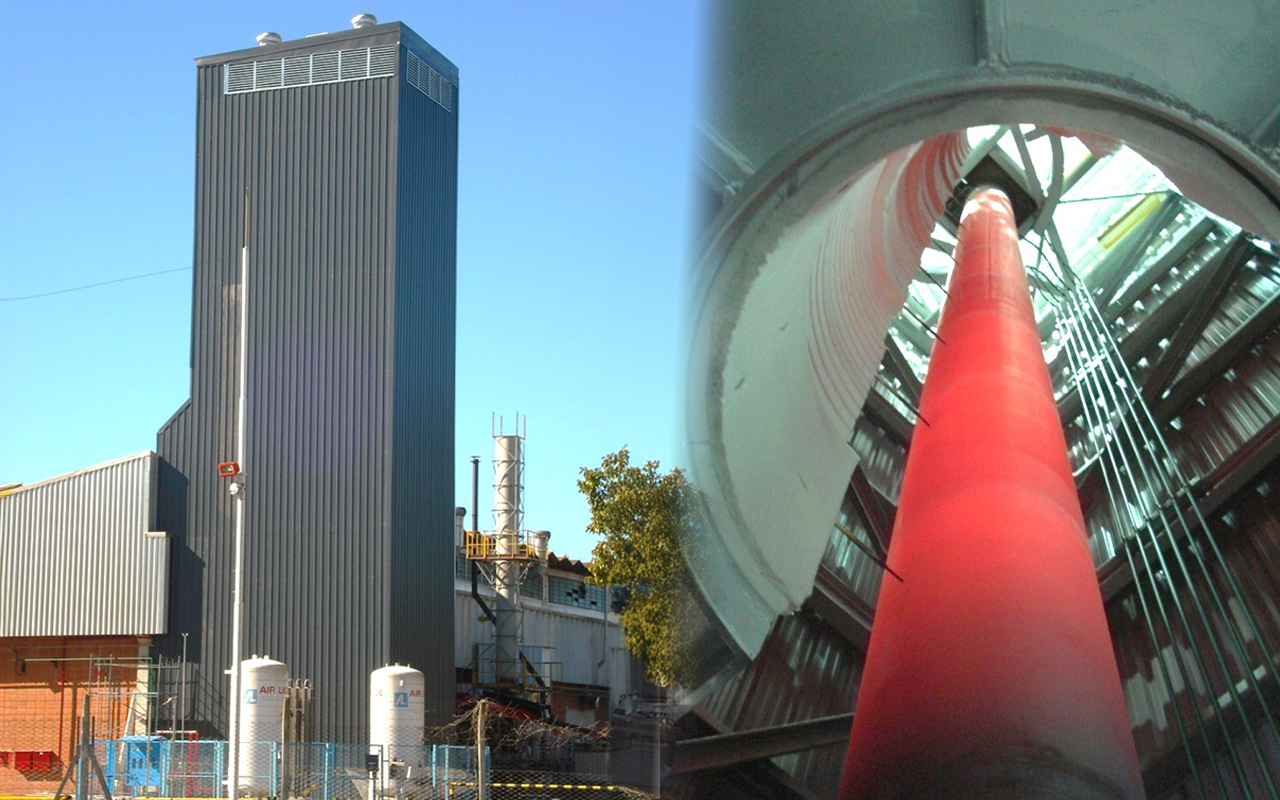

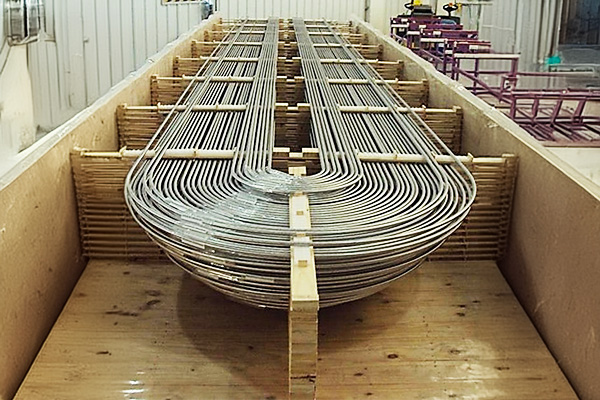

We manufacture high quality world class cladding tubes for nuclear fuel bundles, pressure and calandria tubes, seamless and special welded tubes for nuclear, aeronautical and petrochemical markets, made of alloys such as: Zirconium, Nickel alloys, stainless steels, Duplex and Titanium Gr.9 & 2.